Most 'Robots are coming to take away all of our jobs' stories usually read something like this one - 'Chinese factory replaces 90% of humans with robots, production soars' - a recent recounting of the now getting familiar tale of automation becoming more and more of a threat to workers and employment.

You can check out the entire piece on Tech Republic, but here is the essential takeaway:

The Changying Precision Technology Company factory in Dongguan has automated production lines that use robotic arms to produce parts for cell phones. The factory also has automated machining equipment, autonomous transport trucks, and other automated equipment in the warehouse.

There are still people working at the factory, though. Three workers check and monitor each production line and there are other employees who monitor a computer control system. Previously, there were 650 employees at the factory. With the new robots, there's now only 60. Luo Weiqiang, general manager of the company, told the People's Daily that the number of employees could drop to 20 in the future.

The robots have produced almost three times as many pieces as were produced before. According to the People's Daily, production per person has increased from 8,000 pieces to 21,000 pieces. That's a 162.5% increase.

The increased production rate hasn't come at the cost of quality either. In fact, quality has improved. Before the robots, the product defect rate was 25%, now it is below 5%

Ooh - that's is the technology double, (really triple), whammy at the expense of workers - cost savings, increased productivity, and better quality. At least in this specific manufacturing example, there just seems to be no way for workers to compete with the robots in this scenario.

So that is the scary, and kind of obvious aspect of the robot takeover, and perhaps for most of the folks reading this blog not one that feels particularly relevant, at least personally. Most of the audience here (and me too), are not manufacturing workers, or even on the 'front-lines' of our businesses for that matter. We work in the more complex, subtle, nuanced, and emotionally tuned-in parts of the business. We have to understand and deal with people, not rigid manufacturing processes. We need to be able to read people, their language, their facial expressions, their tone, and their mood. We need to be able to connect with people. Robots can't do that.

Well, not yet anyway.

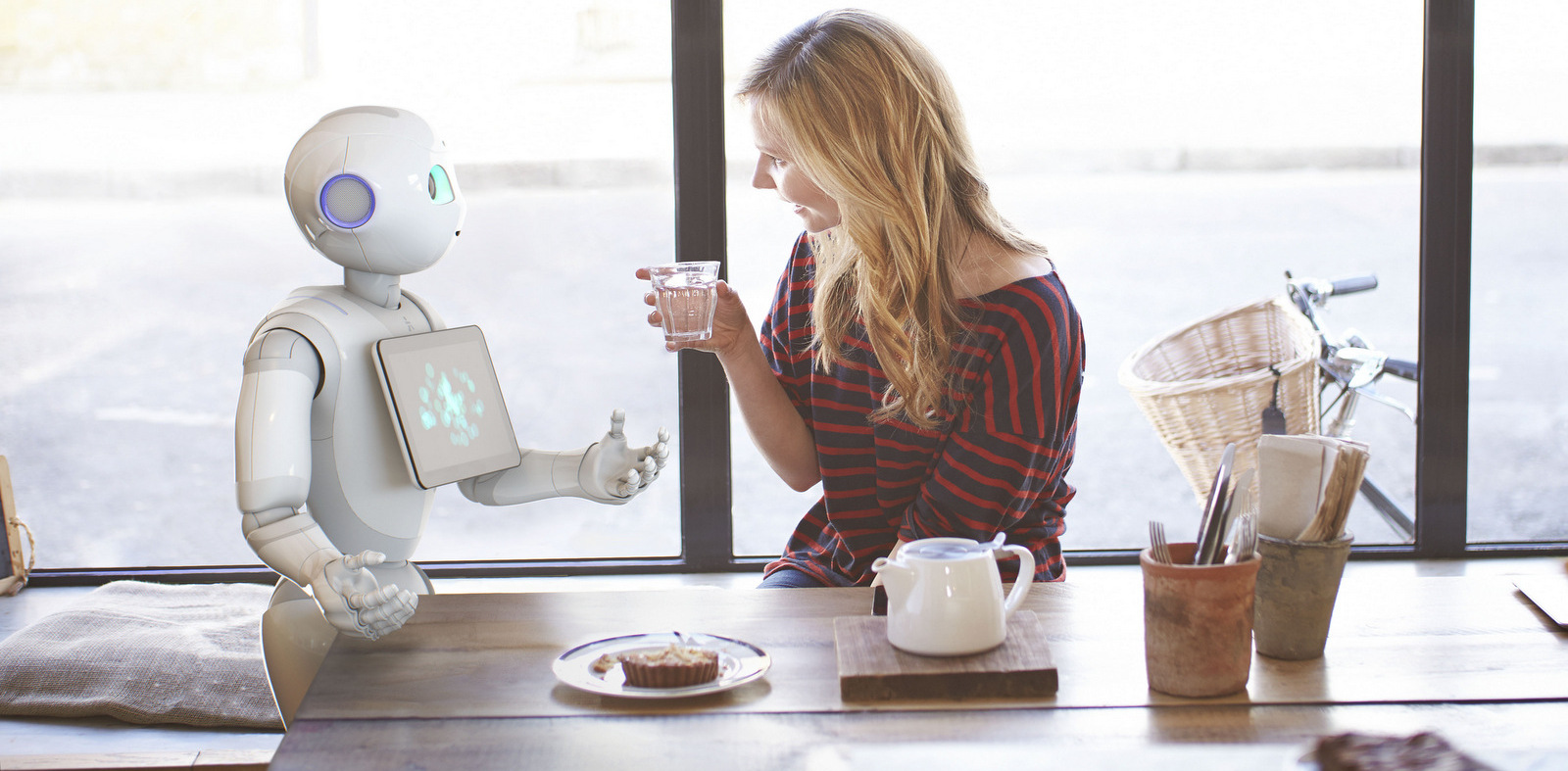

Recently Japanese mobile phone operator SoftBank announced the enterprise availability of Pepper - a humanoid robot designed to be a companion able to communicate with people through the most intuitive interface we know: voice, touch and emotions. Launched first as a personal, and in-home companion, the makers of Pepper envision deployment of the robot in many business scenarios - dealing with customer in a retail setting, educating customers on products and services, and perhaps even entertaining them while they wait for service.

But the interesting part of this is not just what this particular robot can or can't do today, it is what Pepper (and surely others to follow), is designed to be able to do in general. This is from SoftBank's 'Who is Pepper?' website:

To be a true social companion Pepper needs to be able to understand your emotions. If you burst out laughing, he will know you are in a good mood. If you frown, Pepper will understand that something is bothering you.

Pepper can translate what state you are in using his knowledge of universal emotions (joy, surprise, anger, doubt and sadness) and his ability to analyze your facial expression, body language and the words you use. He will guess your mood, and will even adapt to it. For example, he will try to cheer you up by playing your favorite song!

Pepper also can express emotions, and this is what makes him so cute! We can say he has a real personality conveyed by his body language, his funny gestures and his voice.

Reading expressions, gauging your mood from analyzing a complex set of human cues, adapting to you as necessary, and finally, learning from these interactions. Let's suspend (natural) disbelief for a minute and assume Pepper can actually do these things, and is likely to get better and better at all of them over time. If that is the case, what might these developments mean for the rest of us, those of us who don't worry about robots taking over Chinese factories, since we, you know, don't work in Chinese factories?

Robots taking over low-skill manufacturing jobs is only part of the larger automation story, and probably not the most interesting or important part. It is really just replacing one human in a human-process/machine interaction.

Robots like Pepper substituting for human-human interactions? Now that is a story. One that hits much closer to the mark.